MMS’s features are designed to put your team in control of your production.

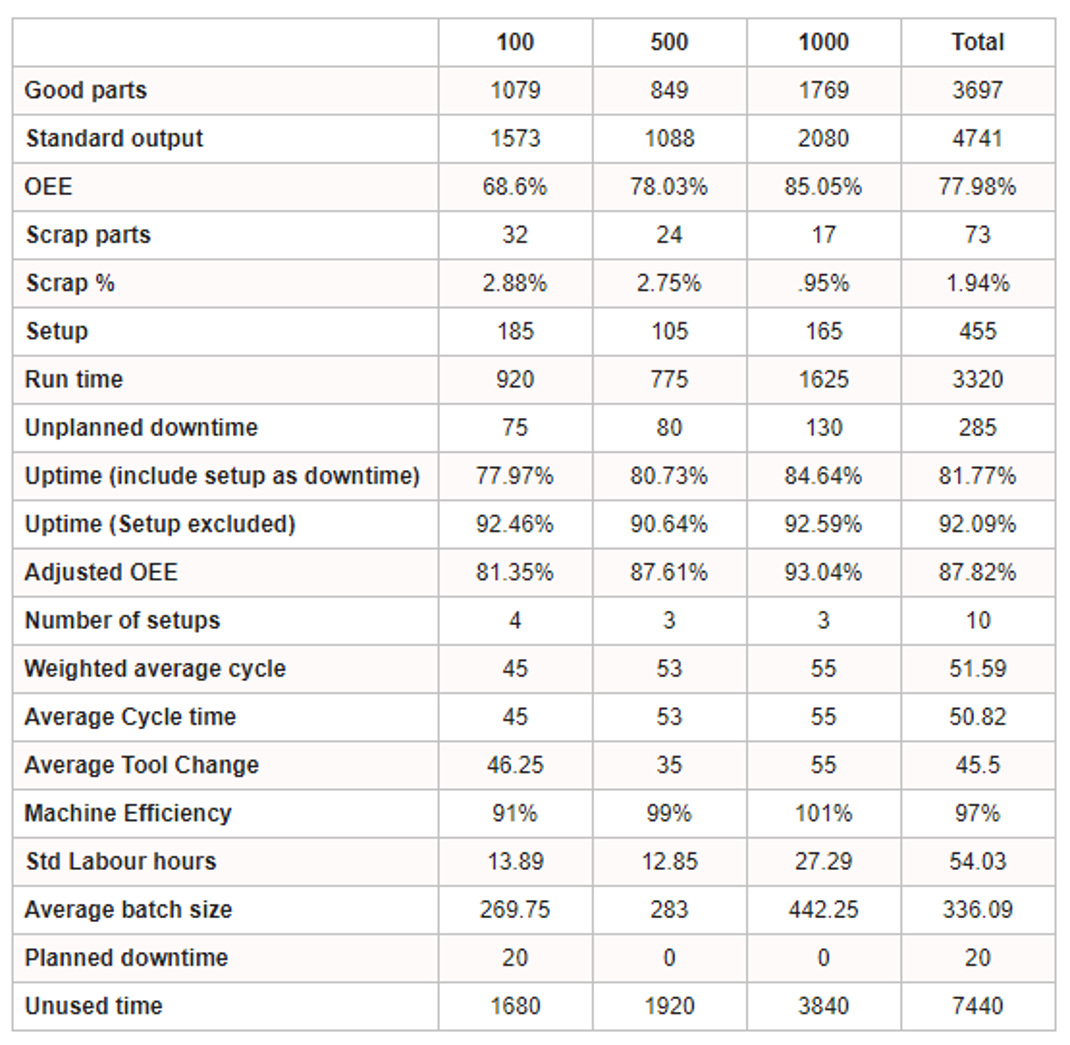

MMS’ downtime analysis identifies the pareto reasons for downtime so you can focus your resources where they can improve uptime the most.

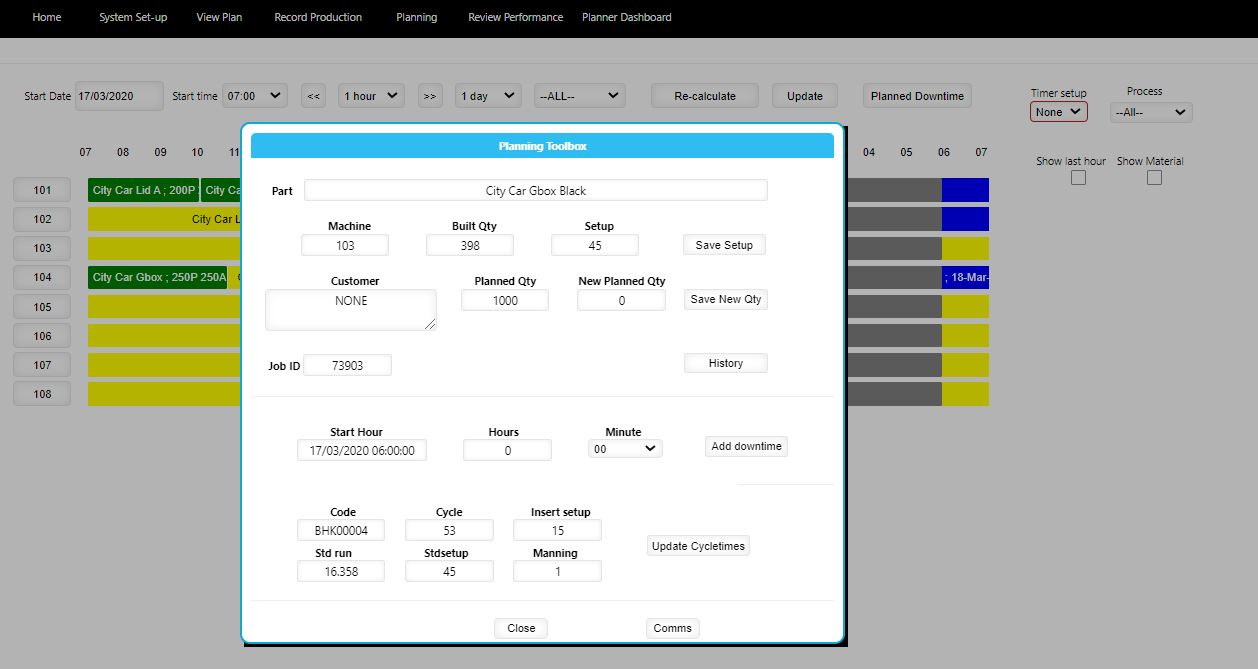

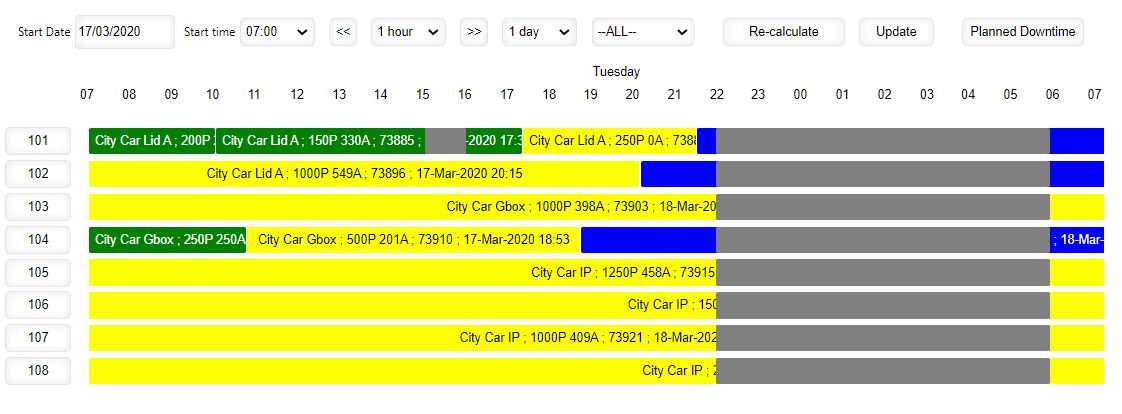

MMS’s planning system is based on standards – not guesswork. It is updated automatically by data capture – no wasted time in planning chasing production for updates. It takes unavailable time like breaks and weekends into account, ensuring your plan is accurate. Over 10 years of development have ensured that the features real-world planners need are available to create and manage the plan as effortlessly as possible.

Plan customer jobs and review against delivery due dates. Use the routing system to create jobs for every process.

MMS features provide every department with a view of the plan. Everybody can see when a job is planned to run and complete and which jobs are already complete. No more expediting upcoming deliveries. No more chasing planning and production for the parts needed further down the plant. No more leaving the customer hanging on the phone while sales coordinators chase planning.

MMS features provide the data you need to run your business when you need it and calculated the way you asked for it. MMS saves your team time and gives them the tools they need to improve your business.

© Copyright 2025 Machine Plan Systems